Aerial cables

A cable for aerial laying has, in addition to its own requirements for its operation, an additional critical requirement, and that is it must be able to support its own weight in the worst conditions. These worst conditions refer to wind and ice and some exceptional issues such as birds perching.

The most important parameter to be taken into account is the length of the span or distance between posts. The cable has to be designed according to this data plus the previous ones of wind and ice.

Depending on the mechanical request, the length of the span to be covered, etc., we can find different types of mechanical reinforcement.

There are 2 main types of cables for overhead lines

- Self-supporting cable. Also called by its acronym in English ADSS (aerial dielectric self supported).

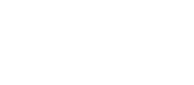

The most commonly used reinforcement in these cables is aramid, because its resistance to elongation is excellent. It is also common for them to be built with a double jacket since, in addition to providing more resistance, it also facilitates the transmission of forces caused by the movement of the cable is minimized to the inner jacket.

Aramid and Kevlar® refer to the same material. Aramid is the common name for the product and Kevlar® is the brand name of DuPont, the manufacturer that created the product.

It is possible and usual to combine glass fibers in cables with aramids. Especially the moisture-blocking fibers.

It is important to point out that when a layer of aramid is added to a cable, when it is installed, the traction must be carried out on the aramid, that is, the hooks, supports or fasteners must be tied to the aramid.

A very interesting and increasingly popular variant as a self-supporting cable is the so-called unitube sheathed micro-module cable with 2+2 fiberglass tensioners embedded in the jacket. They are the KeyMicroflex or F3R cables from Keynet.

These cables can normally be lused in spans of up to 70 meters and have very interesting advantages since, in addition to being used as a self-supporting cable, they are suitable for wall-mounted and piped installation. The subducts are flexible and strip very easily even without a tool.

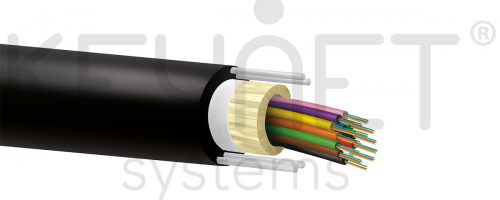

- Cable with steel fastener

From a technical point of view, it is the best solution since all the tension, both in the installation and in the operation, is supported by the steel fastener, leaving the fiber cable free of stress. These cables are also called figure “8” due to the similarity with their sectional cut.

These cables are more expensive and difficult to work with, but their use ensures a long life of the fiber cable without any problem.

A substitute solution for a cable with fastener (also known as messenger) is to lay a separate steel towrope and ‘sew’ the wire to this towrope with a sewing machine.

When analyzing the DTS and MAT values of cables, it is essential to bear in mind that in both cables, but especially in dielectric ones, the most critical value is not the MAT (installation) but the DTS value (operation), since a cable in Aerial laying is constantly working and experiencing a multitude of inclement weather.

Choosing the right cable in every situation, we obtain better results and greater durability in our installations.