The jackets

We have been emphasizing in the previous entries of this blog that different applications require different cables. And one of the most important criteria when choosing the right cable for our project is the jacket.

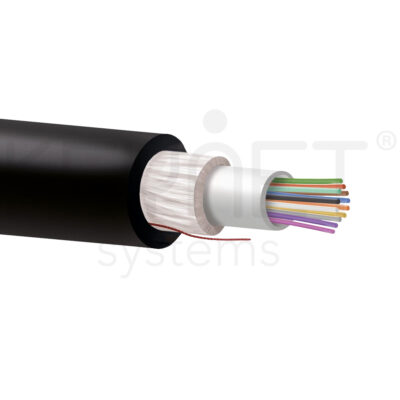

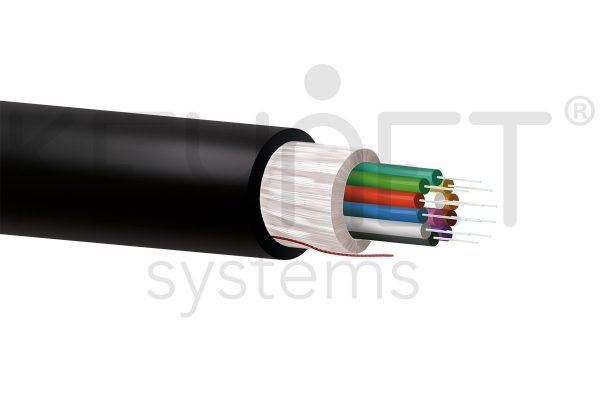

As a general rule, we can divide fiber optic cables into single-jacket and double-sheath cables. Normally we will find double-jacket cables in outdoor uses and mainly inside pipes and aerial lines.

When a double jacket is used, a reinforcing element is added in between them, usually fiberglass, aramid or steel reinforcement.

Following the regulatory standards, if the cable is going to be installed inside a home, public place or when the projecting engineer so determines, the jacket must be made of halogen-free material and classified in accordance with the provisions of the CPR standards, which we will develop in future entries of this blog.

Halogen-free cable, commonly known as LSZH or LS0H, can also incorporate a compound that makes it resistant to the action of UV rays, so the cable won’t be damaged when installed outdoors. As an example, Keynet manufactures all its black LSZH cables with this anti-UV protection. So, if they pass a few meters outside buildings the cables will not be affected by UV rays.

As a summary, a halogen-free (LSZH) jacket must be made of a thermoplastic material that does not include any of the prohibited elements: fluorine, chlorine, bromine, iodine or astatine.

Jackets not halogen free are made of polyethylene. Polyethylene is a highly resistant material that provides greater rigidity, hardness and resistance to abrasion.

The external jackets on double-jacket cables will almost certainly be made of polyethylene, which makes them suitable for indefinite permanence outdoors. Depending on its use, Keynet can be manufacture our wires by adding a bacteria repellent compound for those installations where the cable is buried directly (known as burial cables) or a rodent repellent.

Installations in tunnels and in general where it is necessary to protect the continuity of communication during a fire, the cables can be manufactured in accordance with the IEC60331-25 Standard, whose maximum scale protects the cable for 180′ with a direct flame of up to 750º and even increases the protection in accordance with EN50200 PH regulations up to 90′ with direct fire up to 842º including impact and water.

The jacket is one of the most relevant aspects to take into account when defining the cable of our installation. The durability and the cable to remain in perfect condition for a long time depends largely on the right jacket choice.