10 Good practices in optical fibre installations

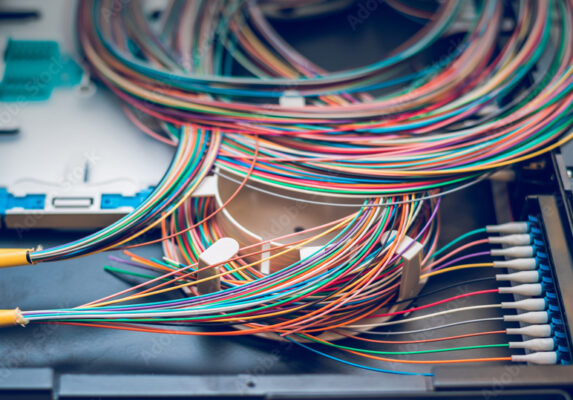

Optical fibre is a data transmission medium that sends photoelectric pulses through a wire made of transparent glass or other plastic materials. These wires can be as thin as a hair, and are precisely the signal transmission medium.

Through these very fine wires, a light signal is transferred from one end of the wire to the other. This light can be generated by a laser or an LED, and its most widespread use is to transport data over long distances, as this medium has a much wider bandwidth than metallic cables, lower losses and higher transmission speeds.

Optical fibre is reliable, safe, light and cheap. It has many advantages over any other transmission systems. But you need to always keep this list of good practices in mind.

1.- Keep all the material, cable and accessories, in a safe, clean, dry place, at a suitable temperature and humidity and away from any mechanical risk. Cable reels must be stored vertically. Try to ensure, as far as possible, a clean and uncluttered work environment.

2.- Always keep the ends protected. The connectors have their own protective caps, do not remove them until the very last moment and have caps on hand when you go to disconnect any device. The performance of the entire installation depends on all connections being made between clean and polished surfaces.

4.- Do not bend the cables more than strictly necessary. Optical fibre is flexible but there are limits depending on the type of cable, you should know in order to not overdo it. Be especially careful when tying or fastening cable bundles.

5.- A cable should never be pulled if it is not using the traction elements that it incorporates. Whether it is a central element, reinforcements embedded in the jacket or aramid fibers, there will always be a point from which the cable can be tied for stretching. Never apply traction on the fibers or the cover.

6.- Do not leave a forced fiber cable. This is often seen in racks and connections. Connections of all kinds must be loose, to avoid tensions of all kinds in the cables.

7.- Never leave boxes open. The cables, accessories, distributors, connectors, facers, etc. must be kept clean inside and out. Cleanliness is essential for the proper functioning of the facilities. Everything in the installation must remain in boxes, racks or closed distributors.

8.- Do not use soap or other unauthorized products to facilitate the sliding of the cables inside the tubes. The chemical composition of the product can damage the cable jacket or get the connections dirty.

9.- All the elements of the installation must be identified and the installation, as a whole, perfectly documented. Document everything as if a person who is completely unaware of the installation had to deal with a breakdown or a reform. That will happen one day and we must leave everything ready for that moment.

10.- The lasers used in FO, even in the testing tools, are outside the visible range, but they are powerful lights that can damage the eyes if you focus them on your eyes or those of another person. Never do it. The fiber is so thin that it can even enter through a pore in the skin. Get used to working with gloves and protective glasses. It is also important to properly dispose of waste after peeling, fusing, etc. safely.

Did you like our post on how to install fibre optics? Did we leave anything out? If so, or on the contrary, if you still have any doubts, please contact us.

💻 keynet-systems.com

📞 976 860 021

📧 info@keynet-systems.com